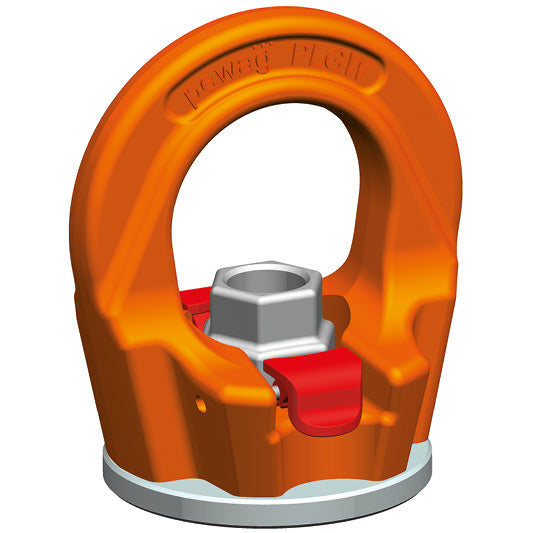

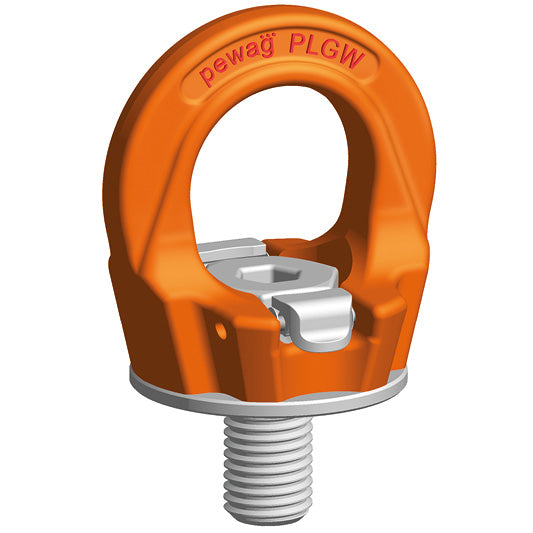

Pewag Profilift Gamma Lifting Point (PLGW-SN)

The Pe wag PLGW-SN screw nut works on the principle of tool-free assembly, which makes it unique worldwide. It takes the successful Pewag PLGW supreme eyebolt one step further and is used on loads that come with a threaded bolt instead of a thread.

wag PLGW-SN screw nut works on the principle of tool-free assembly, which makes it unique worldwide. It takes the successful Pewag PLGW supreme eyebolt one step further and is used on loads that come with a threaded bolt instead of a thread.

Alternatively, the PLGW-SN supreme lifting point may be attached in a through hole using a standard screw, which has the additional advantage of being able to use the same lifting point with different material thicknesses. This method requires just crack-tested screws (strength category 10.9) of different lengths.

The load ring must be placed in the direction of pull before loading – do not turn under load!

For additional details and information, please refer to the full operating manual.

Further benefits of the PLGW-SN Pewag Winner Profilift Gamma Supreme:

• No tools are required for assembly or disassembly

• Saves time, especially if frequent assembly/disassembly takes place

• The lifting point is rotatable (may be set in the load direction) and loadable in all directions

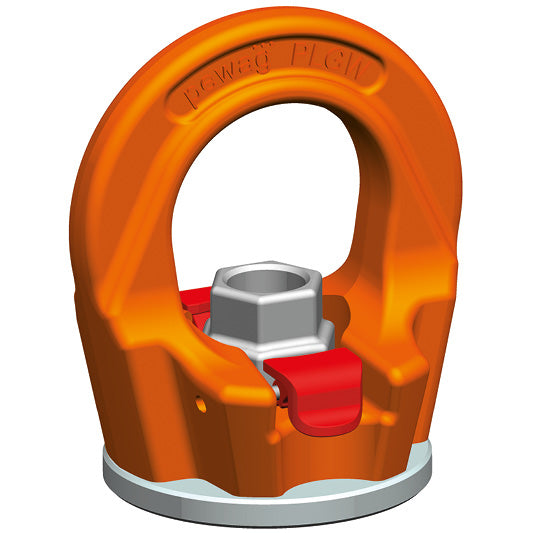

The innovative tool free design of the PLGW-SN lifting eye nut is a patented concept in tool free anchorage by Pewag. This new design allows the lifting eye nut to be tightened and aligned manually in the direction of the load by engaging the special locking clips on to the integral nut which are retained in position via the patented spring. If desired, the eye nut can be tightened using a commercially available ring spanner.

The PLGW-SN is 360° rotatable and has a safety factor of 4:1 against breakage in all directions and can be loaded to full capacity throughout the 180° load range.

Each lifting eye nut is marked with an individual serial number giving full traceability. When used in a vertical lift the capacity can be increased according to the load tables provided.

Each PLGW-SN lifting eye nut is supplied packed with a User Manual which includes load tables for the various applications of use.

Also available with peTAG upon request.

Metric thread sizes available: M8, M10, M12, M16, M20, M24, M30.

Tool-free assembly and disassembly

The clips in position 1 do not have contact with the nut (fig 1)

• The clips are kept in position by the patented spring

• The eye nut is free to rotate

The clips in position 2 are in contact with the nut (fig 2)

• The clips are kept in position by the patented spring

• The eye nut can not rotate i.e. the fastening torque is transmitted to the nut which can now be tightened or unscrewed by hand.

Permitted usage

Ensure that the PLGW-SN load capacity is in accordance with the inspection certificate, the loads are within the permissible direction of pull and also within the WLL stated in the tables supplied. The locking clips must be disengaged to allow free rotation of the eye to the line of pull of the load.

Adjust the lifting point in the permitted load direction before loading.

• Loadable with a 4-fold safety factor under break in all directions

Non-permitted usage

During assembly, ensure that improper loading cannot arise due to any of the following factors:

• Direction of pull is obstructed

• Direction of pull is not within the indicated area

• Loading ring rests against edges or loads