Pewag Profilift Delta Lifting Point (PLDW)

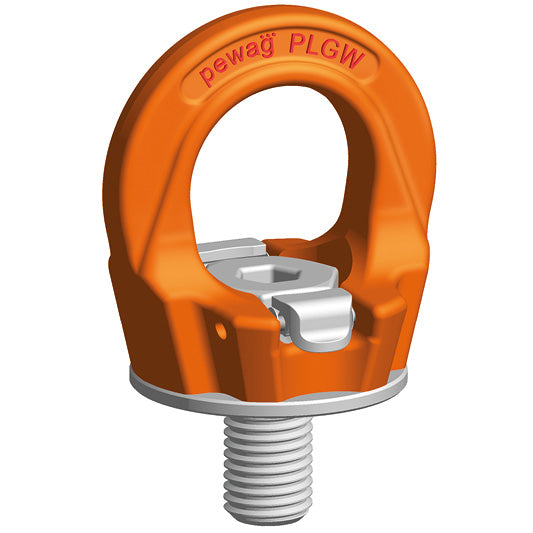

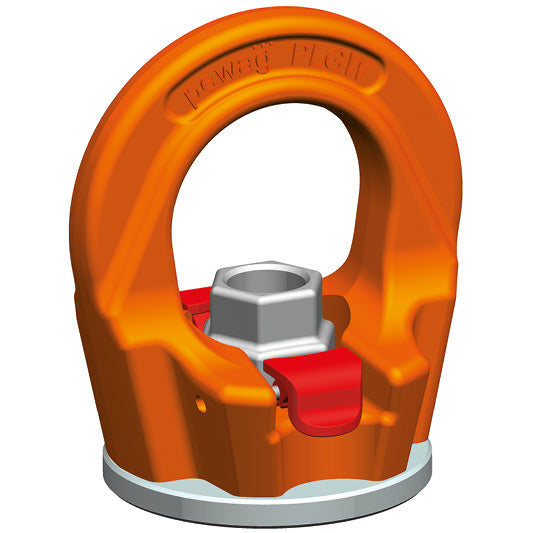

The Pewag Profilift PLDW lifting and lashing point utilizes a ball bearing which allows the unit to be rotated 360° even under load. A high strength free moving lifting eye is incorporated in the design and is movable by 180° and is wide enough to accommodate larger hook sizes. The special screw is 100% crack-tested, protected against corrosion and marked with the load capacity and thread size.

In addition, each lifting point is marked with its own individual serial number providing full traceability. The PLDW range is available with metric threads and can also be supplied with long (max.) or custom bolt lengths which are supplied with a special 100% crack detected prevailing torque type locking nut and washer to DIN 980-V (PLMS).

In addition, each lifting point is marked with its own individual serial number providing full traceability. The PLDW range is available with metric threads and can also be supplied with long (max.) or custom bolt lengths which are supplied with a special 100% crack detected prevailing torque type locking nut and washer to DIN 980-V (PLMS).

All load capacities, categorised by method of lifting, number of legs and angle of inclination are contained in a table that forms an integral part of the operating manual included with each lifting point. The Pewag Winner Profilift Delta lifting points are marked with the admissible load capacity for the most unfavourable application mode, allowing for an increased load capacity in case of vertical loads and a 4:1 factor of safety against break in all directions.

Also available with peTAG upon request.

Metric thread sizes available: M8, M10, M12, M14, M16, M20, M22, M24, M30, M36, M42, M45, M48, M52, M56, M64, M72, M80, M90, M100.

UNC thread sizes available: 3/8", 1/2", 5/8", 3/4", 1", 1 1/8", 1 1/4", 1 1/2", 1 3/4", 2", 2 1/2".

Permitted usage

Can be loaded in all directions within the 180° range.

For load capacities in the permitted directions of pull, please refer to the load capacity table.

Non-permitted usage

During assembly, ensure that improper loading cannot arise due to any of the following factors:

• Direction of pull is obstructed

• Direction of pull is not within the indicated area

• Loading ring rests against edges or loads

Despite the upper part being fitted with a ball bearing and being rotatable 360°, before use, you should adjust the ring in the correct direction of tension. This applies in particular when lifting with multi leg slings. With a non-aligned ring, the ring holder could turn suddenly under load creating a potential risk for the load and/or people.

The full operating manual contains further details and information on safe usage.

Calculating the required thread length (L):

L = H + S + K + X

H = Material height

S = Thickness of the washer

K = Height of the nut (depending on the thread size

of the screw)

X = Excess length of the screw (twofold pitch of the screw)

L max. = n max.

In addition to the standard and maximum thread lengths, Pewag also offers cut-to-length thread lengths.

Customised and maximum thread lengths are supplied with a washer and a crack-tested, corrosion-proofed screw nut.

For detailed information such as method of lifting, number of legs, angle of inclination etc., please refer to the tables with technical data.